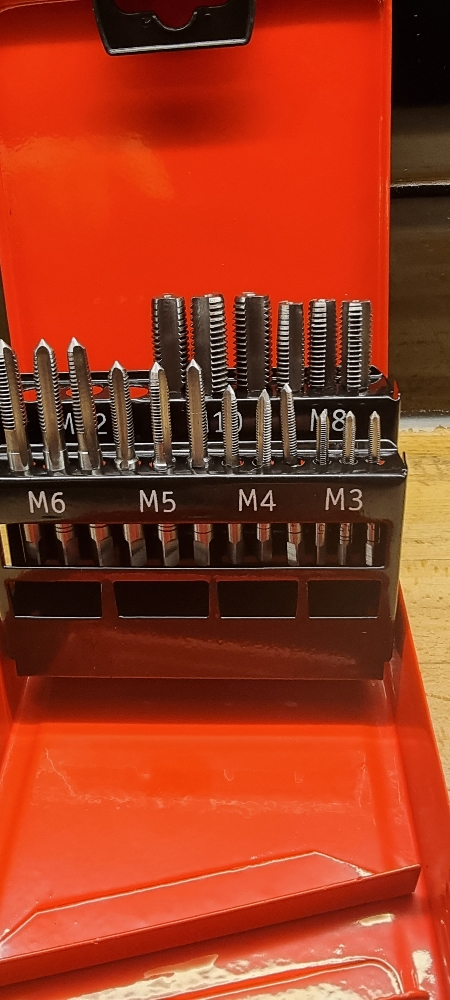

So after reading all this and inspecting my rotor bolts I decided that I would replace them after all. I took them out last night (using a heat gun, cheers JamieMac) and they all came out without any issue whatsoever. Tonight I tried to fit the new rotors and new bolts and there's a problem. 9 bolts go in no problem at all, and one doesn't. I get it halfway down, then it doesn't feel like it wants to go any further. I didn't force it, just took it out and tried a few things:

1. Cleaned the screwhole with wd40 and a cotton bud to clear out any debris I missed last night

2. Tried different bolts - new and old - everything stops in the same place..

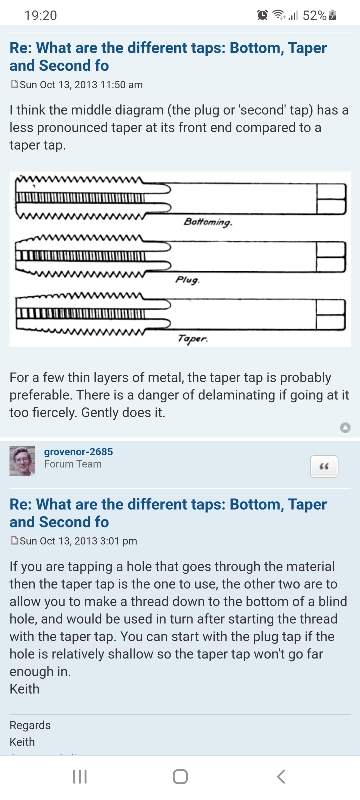

So, it feels like it has cross threaded... I don't want to force it down....

Thoughts?