stuartb

Well-known member

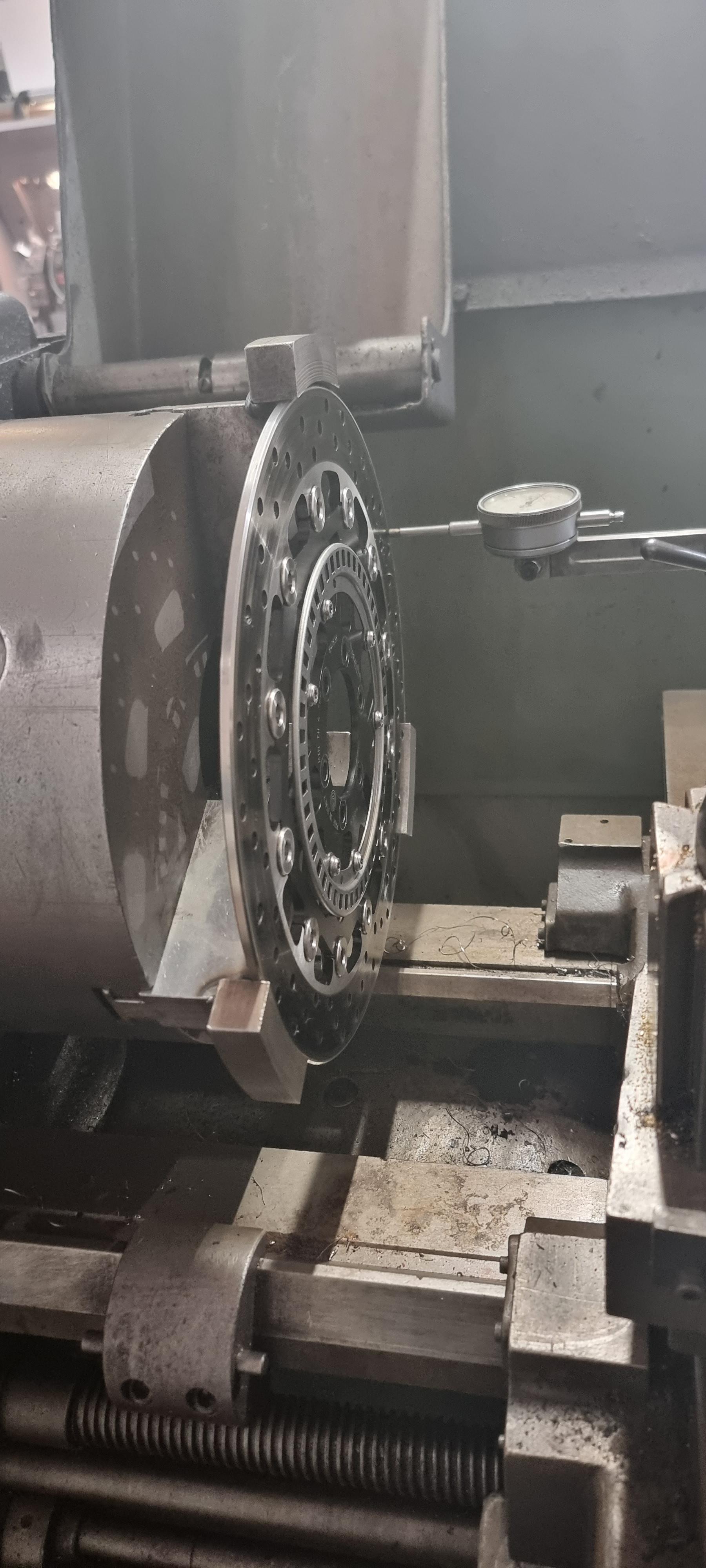

Anyone know the runout tolerances on front discs ?

Sent from my SM-G998B using Tapatalk

Sent from my SM-G998B using Tapatalk

Cheeky *******... [emoji1787] ..Does the RS4 even go quick enough to warrant them lol

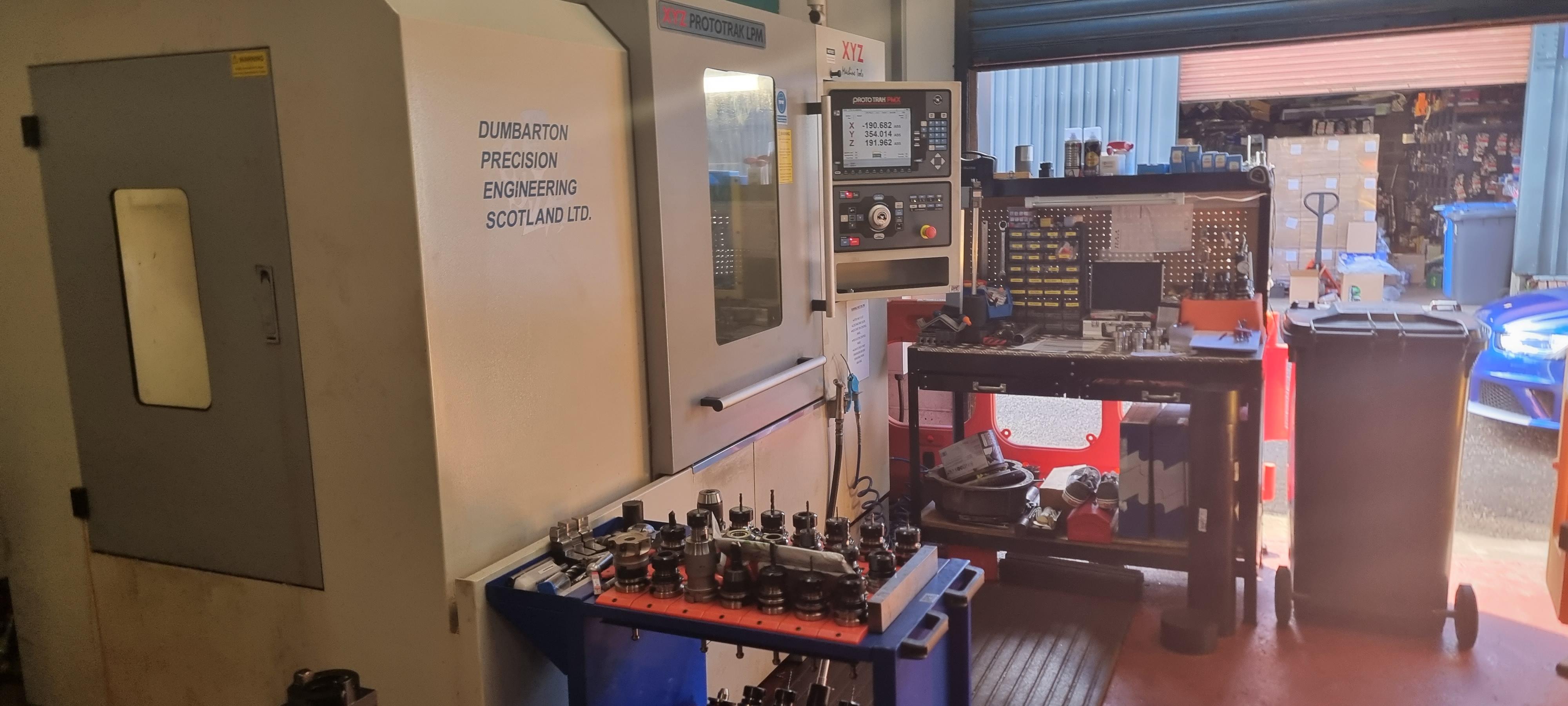

Muddled my way through it you mean haha.. and so am I..Sounds like you're doing a thorough job as always Stuart. I'm intrigued to find out what's causing it.

Enter your email address to join: